An introduction to North American electrics

The American electrical system is quite interesting and has some notable differences compared to how things are done in many other parts of the world, though it has also had its own set of influences in other countries. This page will mostly talk about practices in the US and Canada, though Mexico uses very similar standards too.

Most appliances run at 120V 60Hz, though 240V is available for more powerful devices on dedicated circuits. Industrial installations are often connected to a 480V (or 600V in Canada) three phase supply.

Safety features tend to be less common compared to European installations; this is partially caused by technical challenges due to breaker panel design and the high number of circuits but likely also derives from a lax sense of safety due to the lower voltage.

Plugs and sockets

American plugs have two flat blades for the line (hot) and neutral, as well as a circular or semi-circular pin for the earth (ground) connection on three-prong plugs. Plug standards are regulated by NEMA, the most common being types 1-15P and 5-15P, respectively the non-earthed and earthed 15A 120V types.

Non-earthed plugs are often polarised, that is, they preserve the distinction between line and neutral. This is accomplished by having the neutral blade wider than the line one, thus only allowing the plug to be inserted one way. Earthed plugs are always polarised due to the presence of the earth pin.

While this plug design is very compact, its main disadvantage is the ability to accidentally touch the pins of the plug while connected half-way, which could potentially cause an electric shock.

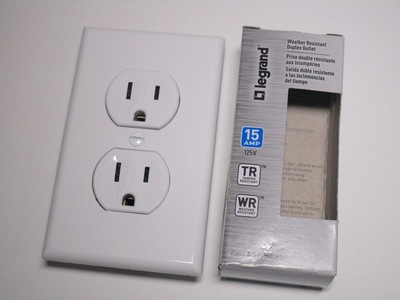

Power sockets fit in rectangular wall boxes and are usually duplex receptacles. 15A ones (NEMA 5-15R) are by far the most common and can be connected to either 15A or 20A circuits. 20A ones also exist, but are uncommon in residential applications. Various other types of outlets exist for high-power and industrial uses.

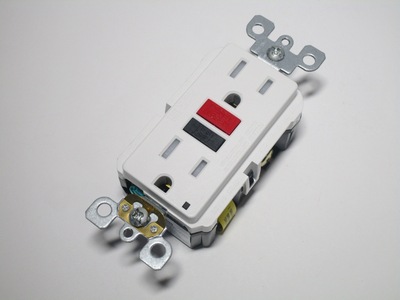

In wet areas such as kitchens and bathrooms, GFCI (RCD) sockets are mandatory and widespread, to provide protection in case of a shock. They feature buttons to test and reset the GFCI functionality as well as "load" terminals on the back to connect to additional sockets.

TR (tamper-resistant) outlets fitted with safety shutters are nowadays required in most areas, though as this is a relatively recent change most houses haven't been fitted with them yet.

Light switches and other accessories

Standard American light switches have a small rectangular post which is moved up and down to toggle the switch, a design not found anywhere else in the world. More modern installations use paddle-style switches, which have a large surface that's simply pushed on the top or bottom, similarly to European designs. Combined accessories are also available, such as a combined socket and light switch.

Traditionally, different wall plate types have been used for sockets and switches, which were thus incompatible. Faceplates meant for larger wall boxes had to account for this and had to be available in all sorts of variations. Nowadays, however, the large "Decora" style initially only utilised for GFCI outlets has become popular, and is likely to become the standard in the future.

Split-phase supplies

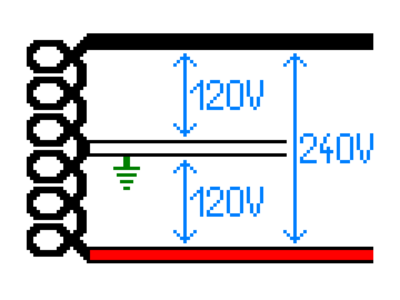

Something specific to North American wiring is the use, in residential installations, of split-phase supplies. These are single-phase supplies where the transformer has a centre tap, connected to earth to form the neutral; because of this, three wires are supplied instead of two: the neutral and two line (hot) wires, often referred to as phases.

Between either of the two line wires and the neutral, 120V can be obtained, for use in socket circuits, lights and other standard appliances. When measuring between the two line wires, however, a potential of 240V is available. This is used for most high-power devices, such as electric stoves, dryers and AC units. Special sockets are available for this purpose.

The earthing system used is TN-C-S, with the split between the combined earth and neutral happening inside the first point of disconnection - usually the breaker panel, through a bonding screw which connects the supply neutral to the metal chassis of the panel.

Breaker panels

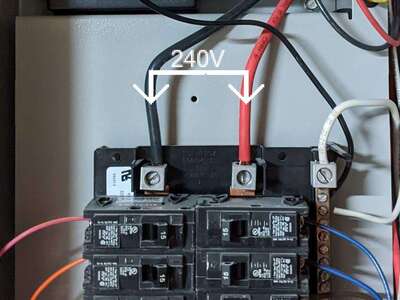

Breaker panels are considerably bigger than elsewhere in the world; this is due to the higher number of circuits, a result of the limited power available under 120V. Circuits are powered from either a 15A or 20A breaker, with the latter having become more common over the years, and often are shared between sockets and lighting. Despite the relatively low power available to each circuit, household supplies tend to be quite large, with 200A 240V (48kW) being common.

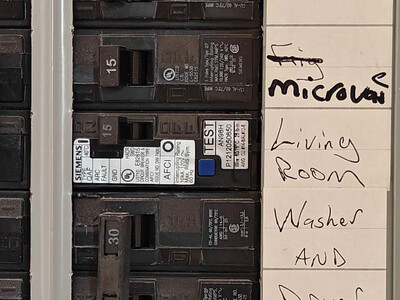

The design of the panels is only partially modular, with a single fixed busbar - fed from a main breaker - which then all breakers connect to. The busbar alternates between phases, allowing the use of double-pole breakers for 240V circuits and helping with load balancing. Installing a breaker is very easy, as it simply clicks into place. Some newer panels use a "plug-on neutral" connection, which avoids having to connect the neutral lead from a GFCI or AFCI breaker.

GFCI (RCD) protection is quite uncommon and is usually only found in "wet areas" (kitchens and bathrooms), using a GFCI outlet. The reason for this is, likely, the high cost of using a GFCI breaker for each circuit, while the single busbar makes it impossible to have a single GFCI feeding multiple breakers. More recently, AFCI breakers, protecting against arc faults - a fire risk - have become mandatory on certain types of circuit and thus found in newer installations.